Background

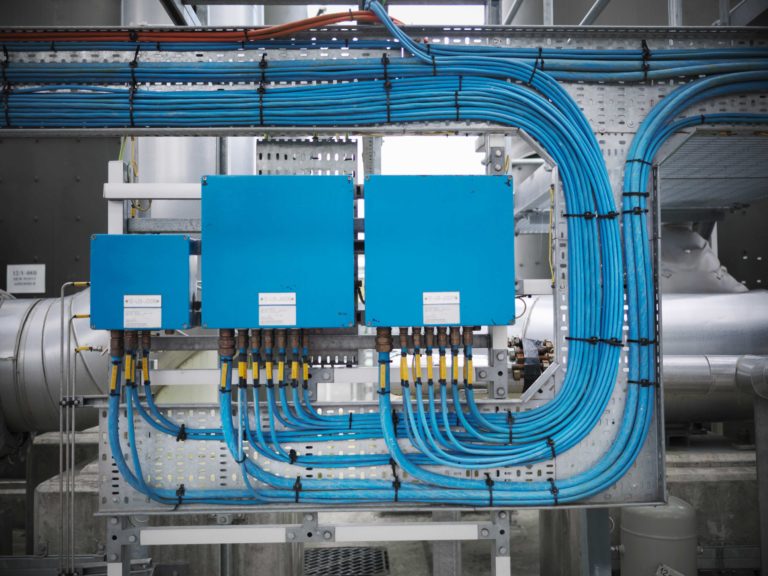

Verification of mechanical and pipe vibrations for structural integrity.

Assignment

Efterklang is helping Vatten och Miljö i Väst AB with its verification of vibration requirements for machines and piping systems in order to ensure a 50-year lifespan at Kvarnagården Water Treatment Plant in Varberg. Even a stationary machine can experience wear and tear due to vibrations from other pumps and machines, resulting in reduced service life. Varberg, which is an expanding municipality, has invested in improved water treatment to ensure both the safety and quality of drinking water. Production capacity is approximately 26,000 m³/day.

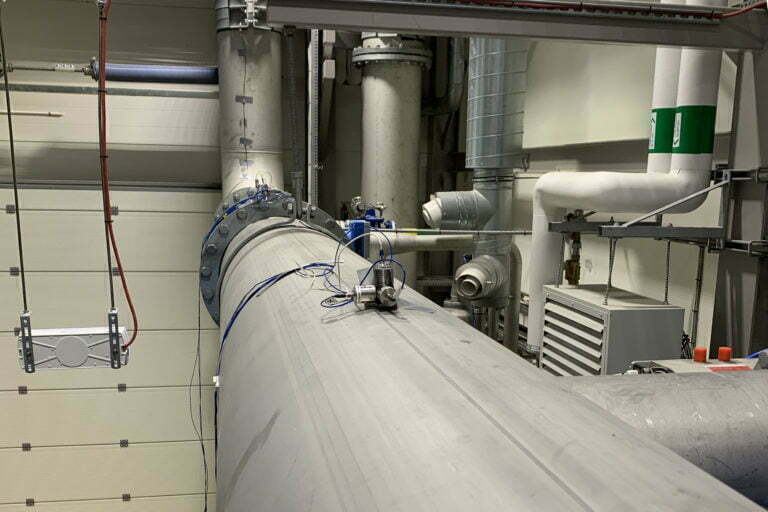

Kvarnagården Water Treatment Plant is equipped with so-called NOM ultrafilters that purify the water. Membrane filters constitute a method for accessing increasing concentrations of ‘Natural Organic Matter’ (NOM) and increasing color numbers in incoming raw water. Improved NOM separation occurs through direct precipitation over the membranes. The technology requires that flushing and backwashing to be carried out over the membranes, which in turn gives rise to transient vibration loads in the piping systems.

Result

The undertaking began in 2017 and is still in progress.

Image: Illustrative